Our goal is to minimize the impact on the environments where we operate and to preserve and restore them for future generations as best we can after mine closure. We work cooperatively with local communities, governments, and other stakeholders to achieve this goal and to learn how to improve our environmental performance.

The application of our Environmental Policy enables us to pursue responsible management of energy, water, emissions, residues and waste, our impacts on climate change and to protect natural resources and biodiversity in compliance with the applicable laws of the countries where we operate.

Environmental Management Systems

Our Caylloma Mine has an ISO 14001 environmental management system in place. ISO 14001 provides tools and standards that guide the management of our environmental responsibilities. Caylloma was first ISO 14001-certified in 2010 and most recently re-certified in 2019.

At our San Jose Mine, the environmental management system complies with ISO 14001; the operation is yet to be certified. The environmental management plans at San Jose are approved by the Ministry of Environment and Natural Resources (SEMARNAT) and meet the requirements of the environmental impact studies authorized by the National Water Commission (CONAGUA) and SEMARNAT.

WATER

Water is a vital resource for life. In cooperation with the local communities, we share the responsibility for caring for water resources and protecting the ecosystems around our operations.

Water is a vital resource for life. In cooperation with the local communities, we share the responsibility for caring for water resources and protecting the ecosystems around our operations.

Mining operations rely on water for particular activities, including mineral processing, dust suppression, material transport, and human consumption. Water is valuable and essential, and we are accountable for its rational and reasonable use as well as the prevention of potential impacts on water resources.

Our approach to water management is governed by our Environmental Policy and the approvals and regulations established by the environmental authorities of the countries where we operate. We focus on minimizing water collection and maximizing water reuse as much as possible.

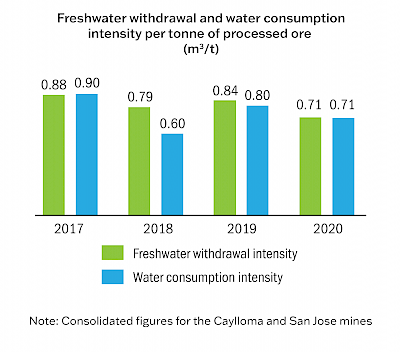

We measure our water management performance primarily by calculating the freshwater consumed per tonne of processed ore in cubic meters per tonne (m3/t). Our enduring goal is to reduce the freshwater collection intensity by finding opportunities for improvement.

-

Water Sourcing at Caylloma, Peru

The freshwater source for our operations at Caylloma is the Santiago River. By focusing on water reuse, we only require approximately half the currently authorized freshwater withdrawal capacity. We monitor eight effluent discharge points at the site and report monthly on our water consumption and quarterly on quantitative monitoring results to the National Water Authority (ANA).

The freshwater source for our operations at Caylloma is the Santiago River. By focusing on water reuse, we only require approximately half the currently authorized freshwater withdrawal capacity. We monitor eight effluent discharge points at the site and report monthly on our water consumption and quarterly on quantitative monitoring results to the National Water Authority (ANA). -

Water Sourcing at San Jose, Mexico

At San Jose, freshwater comes from rainwater collection in the tailings pond. We also use treated wastewater from the Ocotlan Grey Water Treatment Plant through an agreement with the municipality. The mine has a closed water circuit and does not discharge effluents.

At San Jose, freshwater comes from rainwater collection in the tailings pond. We also use treated wastewater from the Ocotlan Grey Water Treatment Plant through an agreement with the municipality. The mine has a closed water circuit and does not discharge effluents.CASE STUDY: Sourcing industrial water from the Ocotlan Grey Water Treatment Plant is a win-win solution for the community and the San Jose Mine

A portion of the water used at our San Jose mine comes from the Ocotlan Grey Water Treatment Plant we refurbished for the Municipality of Ocotlan de Morelos , a community of approximately 23,000 people, 15 kilometers from the mine.

-

Participatory Water Monitoring

We conduct participatory water monitoring with local authorities and communities, and we identify any type of discharge that could have an impact on water quality. These monitoring activities form part of our plan to ensure that our operations have no negative impacts on the water resources which are important for consumption and economic activities of the region.

We conduct participatory water monitoring with local authorities and communities, and we identify any type of discharge that could have an impact on water quality. These monitoring activities form part of our plan to ensure that our operations have no negative impacts on the water resources which are important for consumption and economic activities of the region.At Caylloma, participatory water monitoring is carried out three times per year, while at San Jose it is done quarterly.

ENERGY

Lowering our energy consumption, increasing our use of renewable sources, and increasing productivity at our operations have both economic and environmental benefits.

At Fortuna, our approach to efficient energy use is governed by our Environmental Policy and we manage our energy consumption in compliance with the approved environmental permits and regulatory frameworks of countries where we operate.

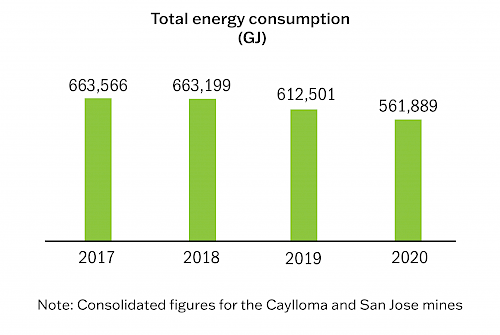

We measure our energy efficiency by calculating our energy consumption per tonne of processed ore. Our goal is to drive this number lower each year with increased efficiency.

Both our Caylloma and San Jose mines use electrical energy supplied by the national grid, and as a contingency measure, we have on-site power generation plants that are used for emergency energy supply. Both the Caylloma Mine and the San Jose Mine use diesel and liquified petroleum gas, primarily for transport. At Lindero, total energy consumption is fuel.

CLIMATE CHANGE

Our activities contribute to climate change just as climate change has the potential to impact our operations, our infrastructure, and the availability of mineral resources. To prepare for these impacts, we are assessing our climate change risks, planning adaptation strategies, promoting the efficient use of energy, and adopting practices to reduce our carbon footprint.

At Fortuna, our approach to managing climate change is governed by our Environmental Policy and we abide by all applicable environmental standards, laws, and regulations in the countries where we operate. As a company listed on the New York and Toronto Stock Exchanges, and subject to such stock exchanges policies and the policies of applicable Canadian securities regulatory authorities, we are obliged to disclose any material risks in our operations, including those associated with climate change. We seek to identify and assess our physical and transitional risks of climate change, and thus manage the impact of climate change on our operations.

Our corporate climate strategy is being developed in 2021, we plan to conduct a more detailed assessment of climate-related risks and opportunities to ensure that our climate strategy focuses on the areas that represent the greatest risks and opportunities to our business. We also plan to develop robust action plans to mitigate risks and capture opportunities, enhance the integration of climate-related risks into risk management processes, set climate-related targets, and increase transparency through disclosure aligned with the Task Force on Climate-related Financial Disclosures (TCFD).

-

GHG Emissions

Electrical power consumption is our main source of greenhouse gases (GHG) emissions. We use mostly non-renewable energy sources to electrify our operations and fuel our transportation.

Our goal is to optimize processes aimed at reducing GHG emissions.

Minimizing GHG emissions is a corporate commitment aligned with our Environmental Policy. We track the intensity of our GHG emissions to help us estimate the overall energy efficiency of our processes and measure the impact we have.

In 2020, we measured the volume of GHG emmissions produced per thousand tonnes of processed ore at the Caylloma and San Jose mines; the Lindero Mine has not yet been considered in this measurement.

AIR QUALITY

We are committed to minimizing the air emissions that result from the extraction, production, and transport activities we undertake at our mine sites.

At Fortuna, air quality management is governed by our Environmental Policy and the environmental standards required by the legislation of the countries where we operate. Our goal is to reduce the pollutant emissions produced by our operations and to ensure compliance with the limits established by regulators.

Our mine operations have air quality monitoring stations to measure and record the amount of particulate matter (dust) and gases in the air. At Caylloma, San Jose, and Lindero mines, we monitor particulate matter less than 2.5 microns (PM2.5) and the gases, nitrogen oxides (NOX) and sulphur oxides (SOX).

TAILINGS AND WASTE

Our goal is to responsibly manage the waste rock, mine tailings and other waste that we produce to reduce our impact on the environment. We are fully committed to managing tailings and waste in ways that prevent and mitigate environmental impacts.

At Fortuna, our management of tailings and waste is governed by our Environmental Policy, our Tailings and Heap Leach Management Standard, and our waste management activities follow the regulatory requirements of the countries where we work.

-

Improving tailings management

As part of our risk management protocols, we are continually assessing our tailings dam and heap leach facilities management systems.

In 2019, we developed the Tailings and Heap Leach Management Standard for our tailings storage facilities (TSF) at the San Jose, Caylloma, and Lindero mines based on guidelines from the Mining Association of Canada and the Canadian Dam Association. The Standard requires that we locate, design, build, operate and close our TSF and our future heap leach facilities (HLF) according to a risk-based approach with site-specific data or as otherwise specified by local regulatory requirements, whichever is more stringent.

Our Tailings and Heap Leach Management Standard focuses on:

- Integrity: Design, construction, operation and maintenance

- Governance: By the owner, responsible engineer and engineer of record

- Monitoring, surveillance and auditing: Including geotechnical instrumentation, and safety reviews and inspections by qualified professional engineers

- Emergency preparedness and response: Including monitoring conditions, assessing and mapping potential impacts, testing, and training in emergency preparedness

In September 2019, we responded to a call issued by the Church of England Pensions Board and others for a global independent public classification system that monitors the safety risk of mining company tailings dams. Our letter includes an inventory of our San Jose, Caylloma, and Lindero TSFs and our management of those facilities. Read our reply to the Church of England Pensions Board request for information on Tailings Dam Management here.

We report on the management of our TSFs in our Sustainability Reports each year.

-

Waste management

In addition to tailings and waste rock, we also generate, manage and dispose of non-rock waste that we classify into two groups: hazardous and non-hazardous material.

At our mines, hazardous wastes include used oil, hydrocarbon-contaminated solids, empty containers of hazardous materials, including empty reagent cylinders and cardboard boxes from used explosives. Non-hazardous waste includes plastic, cardboard, wood, scrap metal, and organic waste. Our enduring goal is to reduce our overall waste generation and increase reuse and recycling at all our sites.

Our main waste management indicator is the amount of waste we generate per tonne of processed ore.

BIODIVERSITY

Our goal is to avoid and mitigate any impact that our activities may have on the diverse species of plants and animals in the ecosystems near our operations.

At Fortuna, our Environmental Policy guides our approach to protecting biodiversity, together with the environmental standards required by the legislation of the countries where we operate. At our operating mines, we have prepared management plans for the protection of biodiversity that are approved by local authorities. These documents include a pre-disturbance biodiversity inventory, biodiversity risk and impact assessments, and a conservation monitoring plan.

We respect areas identified as protected by international conventions, such as the Convention on Wetlands of International Importance especially as Waterfowl Habitat, known as the Ramsar Convention.

The habitats in the areas of influence around our operations serve as a shelter for a wide diversity of plants and animals. Many contain species that are protected at the national and international level.

-

Protecting plants and animals

At both of our operating mines, we conduct biodiversity monitoring twice per year with specialized consultants. We specifically note the occurrence of plant or animal species included on the International Union for Conservation of Nature (IUCN) Red List of Threatened Species and the Convention on International Trade in Endangered Species of Wild Fauna and Flora (CITES).

-

Reducing land disturbance

The wetland habitats and Andean lagoons near our operations at Caylloma in southwestern Peru are of significant biodiversity value and host protected and migratory species. The Peruvian Government considers these two habitats to be fragile ecosystems according to Article 99 of the General Law on the Environment of Peru.

As part of our environmental commitment, we take preventive actions to protect and conserve the flora and fauna species in these fragile ecosystems. This involves various activities, including regular monitoring and awareness sessions.

MINE CLOSURE PLANS

Planning for mine closure starts before mining begins. It is an integral part of any responsible mining operation, from the earliest stages of planning and development throughout the life of the mine.

Our mine closure actions are governed by our Environmental Policy, the regulations of the countries where we operate, and by international standards that require the environmental and social aspects of mine closure be considered from the beginning of operations.

We have committed to making operational and financial provisions for mine closure, rehabilitation and remediation at our mines.

-

Planning ahead

We conduct regular biodiversity monitoring with specialized consultants at Caylloma, San Jose, and Lindero. We specifically note the occurrence of plant or animal species included on the International Union for Conservation of Nature (IUCN) Red List of Threatened Species and the Convention on International Trade in Endangered Species of Wild Fauna and Flora (CITES).

Before we cease mining operations, our mine closure plans and financial provisions are updated and approved by the local regulators and endorsed by the Board of Directors. We send progress reports on the implementation of the plans to local regulators each year.